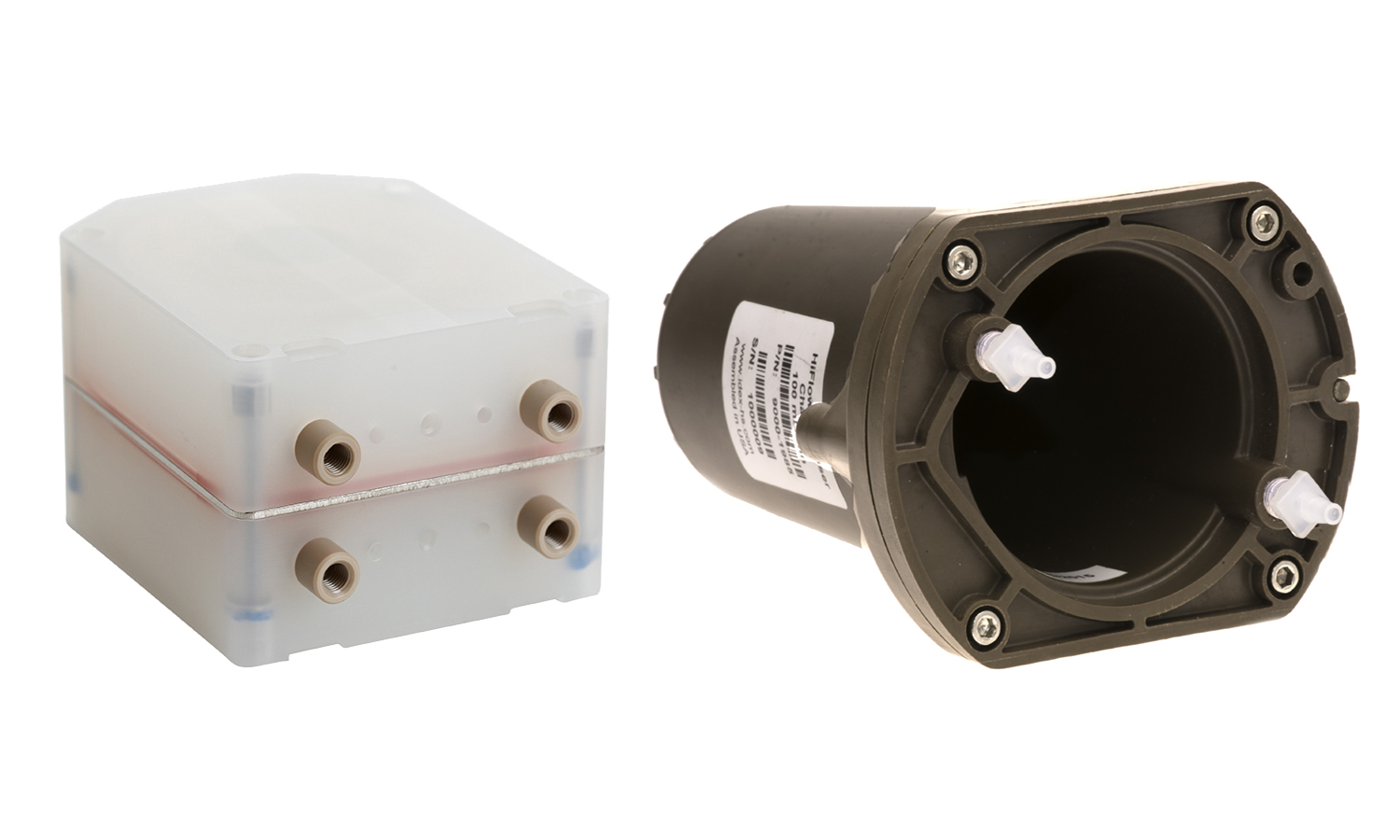

Preparative Degassing Chambers

The standard preparative degassing chamber was designed to be easy to prime, and is configured with a Teflon® AF degassing membrane (tubing) to provide maximum degassing capacity with the absolute minimum internal volume (less than 3% of PTFE designs with comparable degassing capacity) and a chemically inert, metal free flow path. Degassed mobile phase is available in less than a minute!

GENERAL SPECIFICATIONS

- Custom configurations are available. Consult us for your own OEM solution to your specific application.

- The standard prep scale chambers are not recommended for GPC applications or for use with HFIP (hexafluoroisopropanol).

- The flow rates given are for a gradient mixture of 60/40 MeOH/H2O, with a typical low pressure gradient mixing valve. Higher flow rates are possible with high pressure mixing.

- Estimated tubing pressure per unit change in flow assuming laminar flow with a viscosity of 1,0 cP