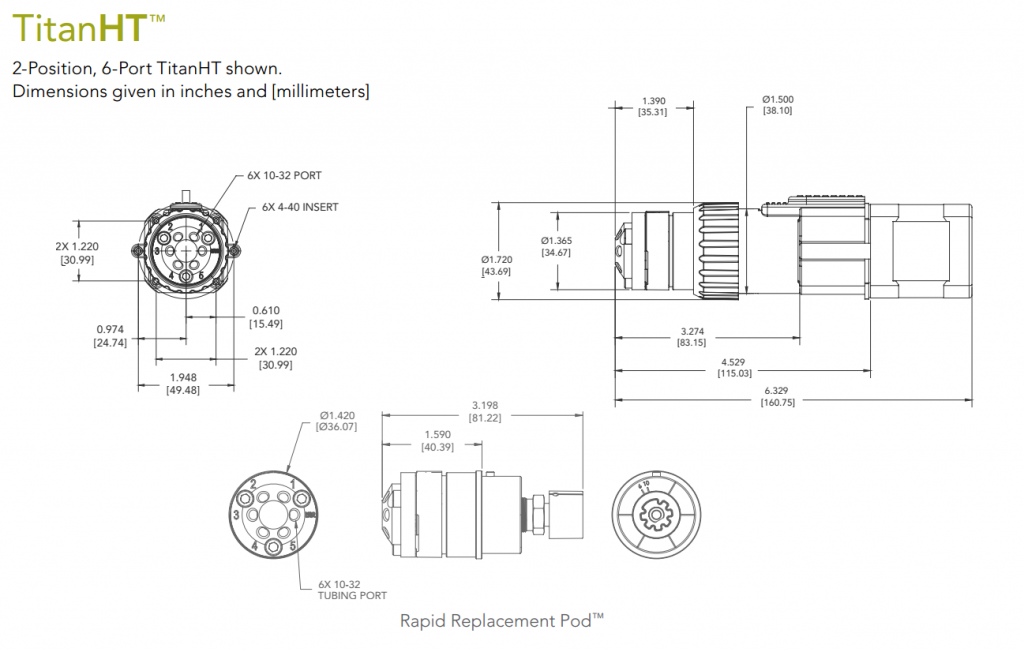

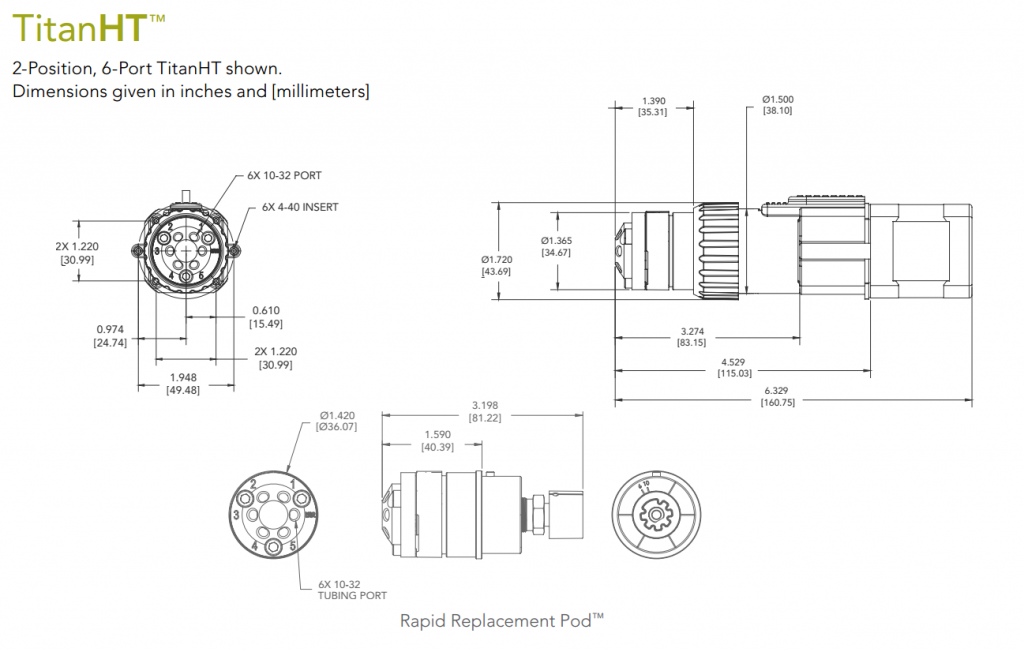

Rheodyne Titan HT and Titan HT UHP

Rheodyne Titan HT

The Rheodyne TitanHT valves provide OEMs with a single solution for nano to prep-scale applications in the next generation of very-high-pressure valve technology. Designed for the high torque demands of the evolving HPLC market, these versatile, multi-position valves are rated up to 15,000 psi (1034 bar).

Rheodyne Titan HT UHP

To address the next generation of Ultra-High Performance Liquid Chromatography (UHPLC) systems, the versatile TitanHT series of fluidic valves for OEM instruments is now capable of 25,000 psi (1,724 bar / 172 MPa).

High Torque, High Pressure

The TitanHT is designed for use in high pressure and very-high-pressure HPLC applications. Using a unique liquidend (Pod) design, the actuator can be separated from the Pod providing flow-path flexibility to accommodate new applications, or next generation HPLC technology.

Principle of Operation

The Rheodyne TitanHT uses shear valve technology; the fluid inlet (stator) remains stationary as a grooved seal on the rotor surface rotates to change port connections. These valves are available in multiple position/port configurations and with different materials for compatibility.

Rapid Replacement Pod™

The Rapid Replacement Pod design of the TitanHT liquidend lends itself to two easy methods of field maintenance. The Pod can be purchased separately and replaced as a unit, allowing virtually no instrument downtime for repair. Or, genuine Rheodyne RheBuild® Kits are available for replacement of just the rotor seal component.

Advanced Composites = Long Life Actuator

Highly inert and wear-resistant, the advanced composite polymers used extensively in the TitanHT valve actuator allow these valves to be actuated maintenance-free* for the life of the valve

Make-Before-Break (MBB®)

Rheodyne valves’ unique, patented MBB architecture design provide uninterrupted flow when switching between LOAD and INJECT positions. MBB greatly reduces transient pressure shocks and is beneficial for flow-sensitive detectors, fragile columns, and pumps. This Make-Before-Break feature extends the life of your column.

Available Driver Board

The specially designed PCB for motor drive and valve control integrates easily into your new instrument. OEM customers only need to provide the digital control signals and 24V DC power in order to achieve random access actuation and position feedback. All valves may be controlled by BCD, I2 C, UART, Pulse or Dual Pulse standards; two-position valves may also be controlled with level logic. In the case where multiple devices need to be controlled, I2 C communication allows up to 128 devices to be connected to a single instrument. The default configuration is level logic for the two-position and BCD for the multi-position valves. Eliminating customer development of board and firmware means shorter product development cycles and reduced time-to-market.

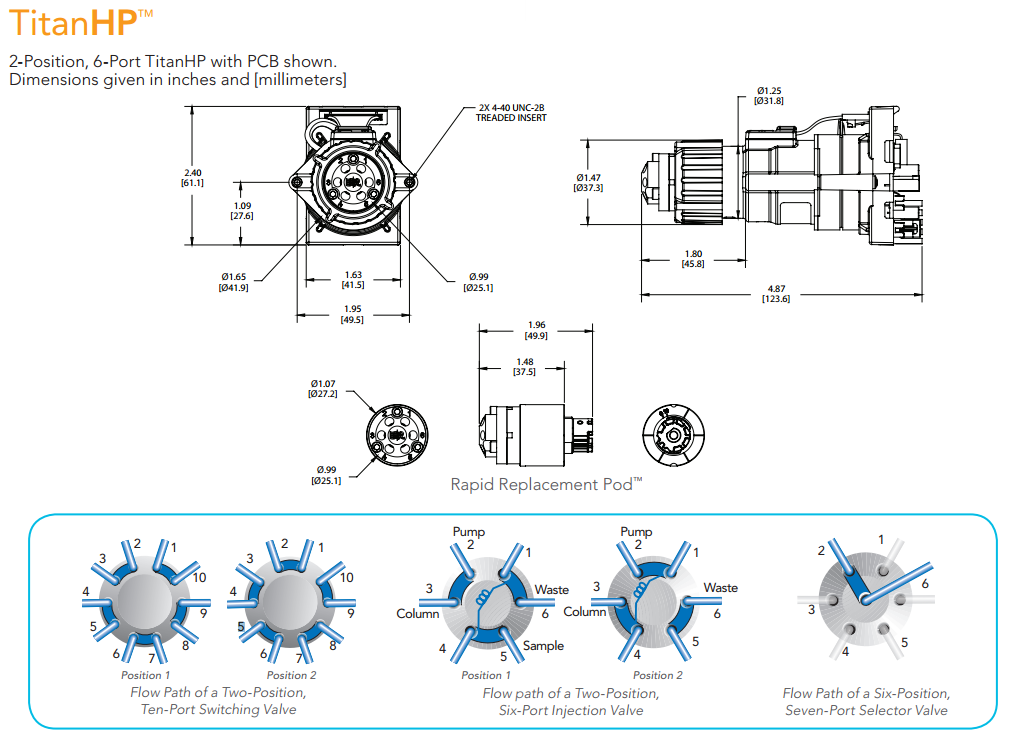

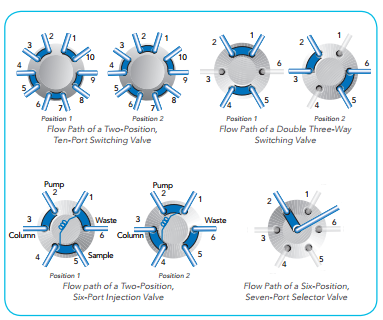

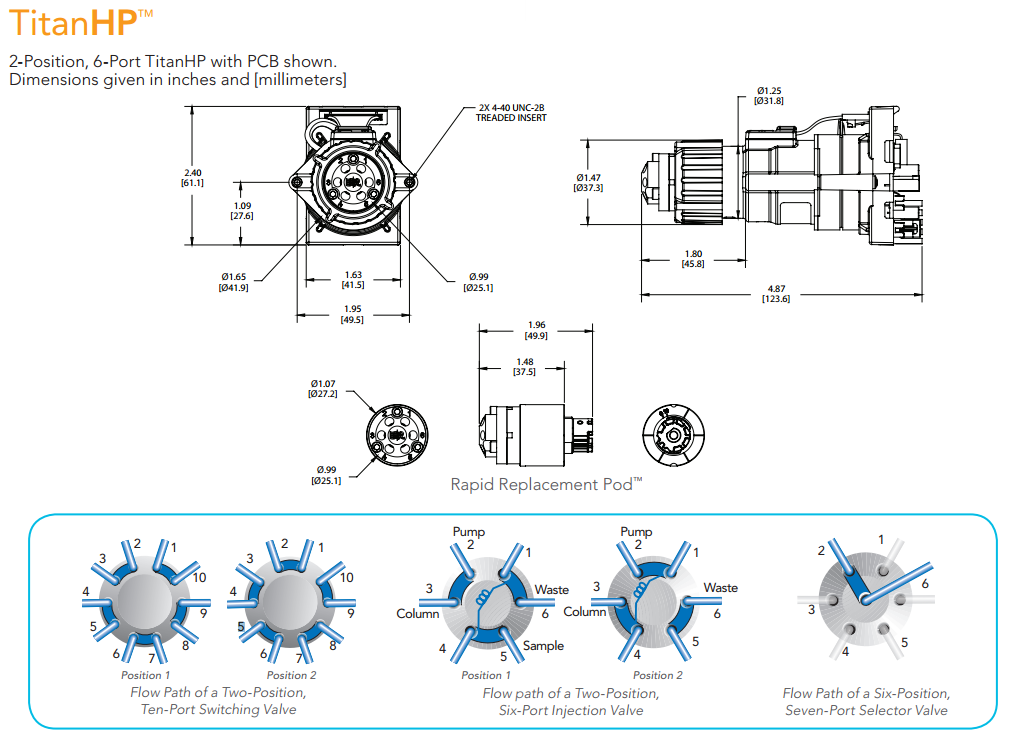

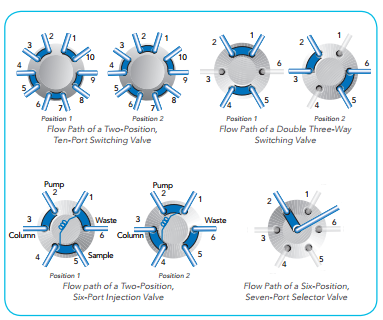

Rheodyne Titan HP

Reliability combined with unique engineering technology make Rheodyne TitanHP valves one of the most versatile and easy-to-use fluidic platforms. The TitanHP consists of an integrated driver/actuator and a removable liquid-end to provide a single, flexible space-saving design. Available for OEMs, these valves are rated up to 6000 psi (414 bar).

Advanced Composites = Long Life

Highly inert and wear-resistant, the advanced composite polymers used extensively in the TitanHP valve actuator allow these valves to be actuated maintenance-free* for the life of the valve.

Principle of Operation

The Rheodyne TitanEX uses shear valve technology; the fluid inlet (stator) remains stationary as a grooved seal on the rotor surface rotates to change port connections. These valves are available in multiple position/port configurations.

Extended Valve Life

The DuraLife® wear surfaces available on the TitanHP valve help reduce frequent replacement of wear components. That means longer in-service cycles and lower field service costs. Biocompatible wear surfaces are also available.

Rapid Replacement Pod™

The Rapid Replacement Pod design of the TitanHP liquidend lends itself to two easy methods of field maintenance. The entire Pod can be purchased separately and replaced as a unit, with virtually no instrument downtime for repair. Or, genuine Rheodyne RheBuild® Kits are available for replacement of just the liquid-end rotor seal component.

Available with Integrated Driver Board

An optional driver board integrates with the TitanHP valves to provide the added functionality of motor drive and valve control without significantly affecting the remarkably small footprint of this multi-position valve. OEM customers only need to provide the digital control signals and 24V DC power in order to achieve random access actuation and position feedback. All valves may be controlled by BCD, I2 C, UART, Pulse or Dual Pulse standards; two-position valves may also be controlled with level logic. In the case where multiple devices need to be controlled, I2 C communication allows up to 128 devices to be connected to a single instrument. The default configuration is level logic for the two-position and BCD for the multi-position valves. Eliminating customer development of board and firmware means shorter product development cycles and reduced timeto-market.

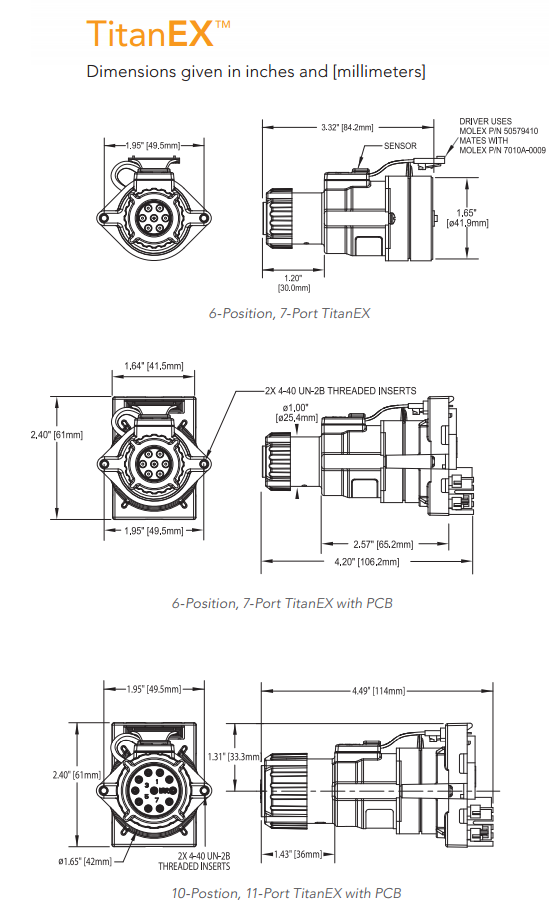

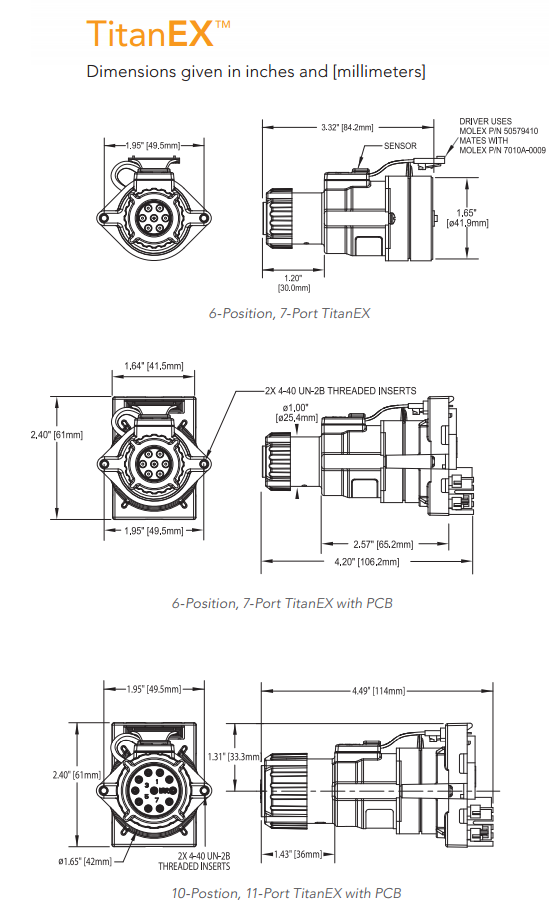

Rheodyne Titan EX

Rheodyne TitanEX valves are a high performance, low-pressure fluidic platform with zero dead-volume. Available in low-cost, small footprint design, the TitanEX is the perfect choice when designing low-pressure instruments for the analytical, biotech, diagnostic, and industrial markets.

Low Pressure, High Performance

The revolutionary TitanEX was designed from the ground up for low pressure (≤125 psi, 9 bar) high performance fluid selection and switching applications.

Principle of Operation

The Rheodyne TitanEX uses shear valve technology; the fluid inlet (stator) remains stationary as a grooved seal on the rotor surface rotates to change port connections. These valves are available in multiple position/port configurations.

Low Cost, Small Footprint

With cost being a frequent OEM concern, the TitanEX is a low-cost, reliable, and quality solution in a space efficient size that can be mounted virtually anywhere.

Unique Tubing Connection System

The TitanEX tubing connection system is unique, patented, and fittingless… all the parts are internal to the valve. The design reduces the tubing/valve interface to a hand-tightening operation that requires no tools. Simply insert the tubing into the ports and tighten the spanner nut. This connection system will accommodate either 1/8” or 1/16” tubing by just exchanging the internal ferrules.

Advanced Composites Mean No Maintenance

Long-life is a principal design criteria of the TitanEX platform. The valve body and internal wear components make extensive use of modern material science by employing advanced composite polymers throughout. These highly inert and wear-resistant materials allow the valve to be actuated over the full operating temperature range without maintenance* during its lifetime.

Available with Integrated Driver Board

An optional driver board integrates with the TitanHP valves to provide the added functionality of motor drive and valve control without significantly affecting the remarkably small footprint of this multi-position valve. OEM customers only need to provide the digital control signals and 24V DC power in order to achieve random access actuation and position feedback. All valves may be controlled by BCD, I2 C, UART, Pulse or Dual Pulse standards; two-position valves may also be controlled with level logic. In the case where multiple devices need to be controlled, I2 C communication allows up to 128 devices to be connected to a single instrument. The default configuration is level logic for the two-position and BCD for the multi-position valves. Eliminating customer development of board and firmware means shorter product development cycles and reduced timeto-market.

Reliability combined with unique engineering technology make Rheodyne TitanHP valves one of the most versatile and easy-to-use fluidic platforms. The TitanHP consists of an integrated driver/actuator and a removable liquid-end to provide a single, flexible space-saving design. Available for OEMs, these valves are rated up to 6000 psi (414 bar).

Reliability combined with unique engineering technology make Rheodyne TitanHP valves one of the most versatile and easy-to-use fluidic platforms. The TitanHP consists of an integrated driver/actuator and a removable liquid-end to provide a single, flexible space-saving design. Available for OEMs, these valves are rated up to 6000 psi (414 bar).